Railway Signalling Electrical Point Machine

What is a Railway Electrical Point Machine?

– An electrical point machine is an electrically driven motor used for the operation of points in railway yards. The rotary motion of the motor is transmitted through the reduction gears and transmission assembly and converted through the linear movement of a toothed rack through a pinion. The gear rack drives switch rails to unlock, changes the position from N to R or R to N, and locks the switch at the end of the stroke.

What is the sequence of point machine operation?

1. Opening of the detection contacts.

2. Unlock the points.

3. Move the points to the desired position

4. Lock the points.

5. Close the detection contacts.

Depending upon the operating voltages

1. Low voltage.DC supplies – 24 volts DC.

2. High voltage DC supplies -110V DC.

3. High voltage AC – 380 AC.

The point machines have split series field windings.

Electrical parameters of point machine

1. Rated voltage – 110V DC.

2. Working current – 4-6 Amps.

3. Obstruction (slipping current) – 6-7 Amps.

4. Operating Time – 3 sec.

5. Type of machine – Combined type. (Operation, locking, and detection)

6. Field winding – Split field

7. Field connection – Series

8. Movement of locking – Rotary type

9. Friction clutch – Self-adjustable

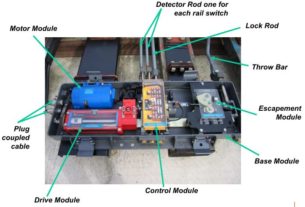

Main parts of point machine

1. DC series split field motor within built-in reduction gear unit

2. Transmission assembly

3. Throw rod, lock slides, and detection slides

4. Detection and control contact switch assembly

5. Hand crank.

6. Spring-loaded friction clutch.

Need for remote control of point machine:

1. To avoid voltage drop in cable cross-section.

2. Contact of lever /knob/push button does not have the heavy-duty current carrying capacity.

3. Track locking is to be provided to prevent point operation under wheels.

4. Point machine should be protected from overload.

5. Facility for sequential operation should be provided.

Two types of relay control units are standardized.

1. Siemens point contactor unit.

2. Point contactor unit with QBCA relays.

Visit here for more information:– https://en.wikipedia.org/wiki/Point_machine

Railway Signalling Electrical Point Machine

Very simple and precise.

thanks

Dear Sir/Madam,

Good day.

Closing Date: 20th January 2019 (ASAP)

Location: Melaka

Qty: 1

Kindly quote your best price and delivery time for the following items below:

Item Description:

Technical Specifications:

Rated Voltage:120V DC -Max Power

Consumption: 0.44kW -Max Stroke: 220mm -Max Thrust: 450Kg ± 50Kg

Max Operating Time: 4 sec Max Operating Current: 5.5 Amp Number of

Contact: 4 Changeover Weight of Machine: 180 Kg -Panel Controller

Control function of movement throw bar by switch when press button (Pull

or Push) with Lamp (LED or Bulb) indication

PLEASE REPLY…URGENT REQUIREMENT

NOTE :

Please include Material, Calibration & Test Certificate where applicable.

Please provide Drawings or Catalogue where applicable.

Please quote together with Transportation Cost.

Your prompt reply is highly appreciated.

Hello Friends

Can we have the information on SIEMENS POINT MACHINES AS WELL AS

NON TRAILABLE INTERNAL LOCK POINT MACHINE TYPE JEA733127A/00

MATTER IS URGENT PLEASE

our email is [email protected] and [email protected]

Need a point interface circuit for 380V 3-phase AC point machine. Request you to share thesame.

ok

Electric point machine(Non trailable,143mm stroke) with threaded type BG Ground connection, IRS

Type, Spec.No IRS S-24/2002(Amd-1).[ Rate including GST and Freight charges]

whay is the ac immunity of crompton point machine