Railway Power Supplies, Earthing and Relay Rack

Power Supply on Relay Rack : • For Vol.2 the power supplies shall be extended from Power Rack to busbars located on relay rack.

• Power supplies shall be located on a separate rack called power supply rack,

• The power supply, transformers, filters and other power supply related equipments shall be installed on the Power Rack which is located in SER.

• In general, three power supplies shall be used, 110V AC(EXT) & 50V DC(INT/ EXT), via appropriately sized wires terminated on separate bus bars via suitably rated MCBs.

• The power supply incoming cables shall be terminated on the bottom of the first MCB (labelled BINDING POST) and on

the top of the first terminal (labelled SUPPLY).

• 110VAC 50Hz(EXT) supply is used to drive the wayside equipments (e.g: FRL, RGI, etc.) and 50V DC(INT) is used for Internal circuits (e.g: Intersig I/O, Point selection circuit, etc.).

• 50V DC(EXT) is used for Trainstop Detection (migration) only.

• Dedicated 110V AC 50Hz (EXT) (e.g: Ready To Depart Indicator etc.), 24V DC(INT) (e.g: SMC PLC I/O cards) and 50V DC(EXT) (e.g: Point heaters) supply is used for SMC PLC related equipments.

• In addition to the above mentioned items, where PDIU control functions are transferred between newly installed

TBTC relay racks and existing equipment, a separate power supply shall be provided from Power Rack to the

new PDIU Relay Rack in SER.

• Wherever practicable the use of the existing supply shall be avoided.

Power Rack

Power supply Busbar :

EARTHING:

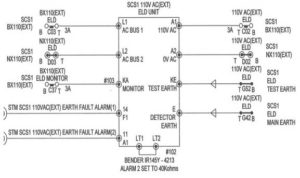

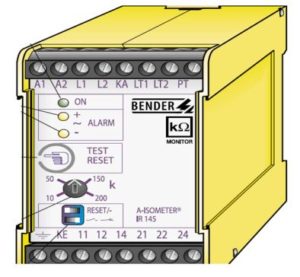

1. The design shall incorporate an Earth Leakage Detector connected to monitor each bus bar supply on the relay rack (50V DC(INT) and 110V AC(EXT)).

2. Each ELD shall require connection to the SER Earth, a separate Test Earth and the B/BX and N/NX terminals of the monitored busbar. The PLC supply will not be monitored.

3. The indications from the Earth Leakage Detector that indicate a fault, will be input to the SMC PLC I/O for

indication purposes.

4. Each relay rack or enclosure shall be earthed via a 16mm sq wire from an earth stud on the rack/enclosure to the SER Earth.

Earth Leakage Detector:

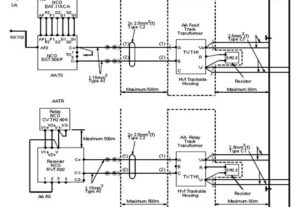

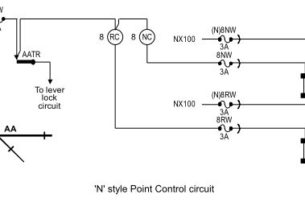

POINT CONTROL CIRCUITS

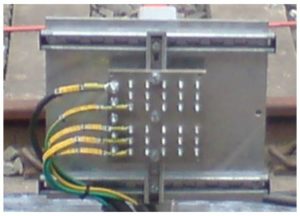

1. All DBOX/CCTBs shall be earthed to the Star Plates using 16mm sq wire from an earth stud on the DBOX/CCTB.

2. Train stops shall be earthed to the running rail using 16mm sq wire from an earth stud on the train stop.

3. RS, Indicators, PESP enclosures, SPKS enclosures, etc. shall be earthed to the Star plates using 16 mm sq wire from an earth stud on the unit except where it can be shown that earthing via conduit or other earthed metalwork is a suitable, sufficient substitute.

Star Plate:

Earth Leakage Detector :

Railway Power Supplies and Earthing, Relay Rack, Power supply Busbar, Power Rack, Earth Leakage Detector, POINT CONTROL CIRCUITS, Earth Leakage Detector